Ensuring health and safety in the fencing business is crucial, especially when dealing with plant and machinery. A well-structured pre-start process can help identify potential hazards, ensure equipment is in good working order, and protect workers from injury. By adhering to these guidelines, fencing businesses can ensure the safety and well-being of their workers while maintaining efficient and compliant operations.

1. Pre-start Meeting

Before starting any work, conduct a pre-start meeting with all team members. This meeting should cover:

- Job Overview: Outline the tasks for the day and the equipment to be used.

- Safety Briefing: Discuss potential hazards and safety measures.

- Roles and Responsibilities: Assign specific roles to team members ensuring everyone knows their duties.

2. Equipment Inspection

Inspect all plant and machinery before use. This includes:

-

- Visual Inspection: Check for any visible damage or wear and tear.

- Operational Check: Test the equipment to ensure it is functioning correctly.

- Safety Features: Verify that all safety features, such as guards and emergency stops, are in place and operational

3. Hazard Identification

Identify and assess potential hazards associated with the use of plant and machinery. Common hazards in the fencing business include:

- Mechanical Hazards: Moving parts that can cause injury.

- Electrical Hazards: Faulty wiring or exposed electrical components.

- Noise Hazards: High noise levels that can damage hearing.

- Manual Handling Hazards: Lifting and moving heavy materials.

4. Risk Assessment

Conduct a risk assessment to evaluate the likelihood and severity of identified hazards. Use the following steps:

- Identify Hazards: List all potential hazards.

- Assess Risks: Determine the likelihood and potential impact of each hazard.

- Control Measures: Implement measures to eliminate or reduce risks, such as using personal protective equipment (PPE) or modifying work practices.

5. Training and Competence

Ensure all workers are trained and competent in the use of plant and machinery. This includes:

- Formal Training: Provide training on the safe operation of equipment.

- On-the-Job Training: Offer hands-on training under the supervision of experienced operators.

- Certification: Ensure workers have the necessary certifications for the operation of machinery.

6. Personal Protective Equipment (PPE)

Provide and enforce the use of appropriate PPE, including:

- Hard Hats: To protect against head injuries.

- Safety Glasses: To shield eyes from debris.

- Hearing Protection: To prevent hearing damage from loud machinery.

- Gloves: To protect hands from cuts and abrasions.

- High-Visibility Clothing: To ensure workers are easily seen if required.

7. Emergency Procedures

Establish and communicate emergency procedures, including:

- Emergency Stops: Ensure all workers know how to use emergency stop mechanisms on machinery.

- First Aid: Provide first aid kits and ensure trained first aiders are on site.

- Emergency Contacts: Display emergency contact numbers prominently.

8. Documentation and Reporting

Keep detailed records of all pre-start checks, training, and incidents. This includes:

- Pre-start Checklists: Document the results of equipment inspections.

- Training Records: Maintain records of all training sessions and certifications.

- Incident Reports: Record any incidents or near misses and investigate their causes.

9. Ensuring New or Modified Plant and Machinery Have Risk Assessment and Training

When introducing new or modified plant and machinery, it is essential to conduct a thorough risk assessment and provide adequate training for safe operation. Here’s how to ensure this process is effectively managed:

Risk Assessment for New or Modified Equipment

- Initial Assessment: Conduct a comprehensive risk assessment before the equipment is used. Identify potential hazards and evaluate the risks associated with the new or modified machinery.

- Control Measures: Implement appropriate control measures to mitigate identified risks. This may include engineering controls, administrative controls, and PPE.

- Review and Update: Regularly review and update the risk assessment to ensure it remains

relevant and effective as the equipment is used and as new information becomes available.

Training for Safe Operation

- Training Programs: Develop and implement training programs specifically tailored to the new or modified equipment. Ensure that all operators receive training on the safe use, maintenance, and emergency procedures related to the equipment.

- Competency Verification: Verify the competency of operators through assessments and practical demonstrations. Ensure that operators understand the risks and safety measures associated with the equipment.

- Ongoing Training: Provide ongoing training and refresher courses to keep operators updated on best practices and any changes to the equipment or procedures.

10. Ensuring Competency for Use of Plant and Machinery

Ensuring that all operators are competent in the use of plant and machinery is critical for safety and efficiency. Here’s how to manage this:

Competency Assessment

- Initial Competency Check: Assess the competency of all operators before they use any plant or machinery. This includes verifying their qualifications, experience, and understanding of safety procedures.

- Practical Demonstrations: Require operators to demonstrate their ability to safely and effectively use the equipment

under supervision. - Regular Reassessments: Conduct regular reassessments to ensure ongoing competency, especially when new equipment or procedures are introduced.

Training and Development

- Continuous Training: Provide continuous training opportunities to keep operators updated on the latest safety practices and equipment advancements.

- Mentorship Programs: Implement mentorship programs where experienced operators can guide and support less experienced colleagues.

11. Keeping Maintenance Records

Maintaining detailed records of all maintenance activities is essential for ensuring the longevity and safety of plant and machinery. Here’s how to manage maintenance records effectively:

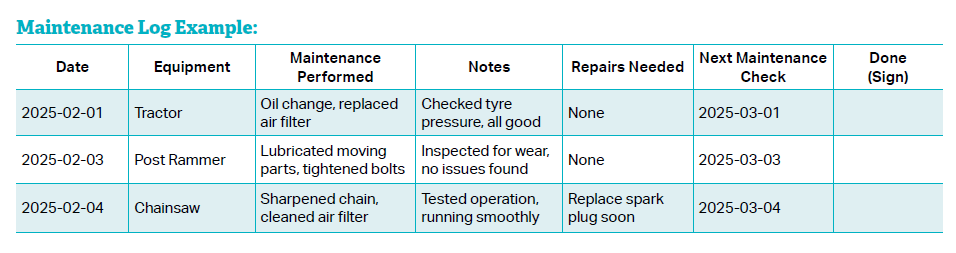

Maintenance Log

- Record Keeping: Keep a comprehensive maintenance log for each piece of equipment. This should include details of all inspections, repairs, and servicing activities.

- Scheduled Maintenance: Document all scheduled maintenance activities, including the date, time, and nature of the work performed.

- Unscheduled Repairs: Record any unscheduled repairs, including the cause of the issue and the corrective actions taken.

Benefits of Maintenance Records

- Preventive Maintenance: Regularly updated maintenance records help in planning and performing

preventive maintenance, reducing the risk of equipment failure. - Warranty Claims: Detailed records can support warranty claims by providing evidence of proper maintenance.

- Safety and Compliance: Keeping accurate maintenance records ensures compliance with safety regulations and helps in identifying potential safety issues before they become serious problems.

Additional WorkSafe NZ Regulations

In addition to the guidelines mentioned above, here are some specific regulations and requirements from WorkSafe New Zealand that are relevant to the fencing business:

1. Health and Safety at Work Act 2015 (HSWA)

- Primary Duty of Care: PCBUs (Persons Conducting a Business or Undertaking) must ensure, so far as is reasonably practicable, the health and safety of workers while they are at work. This includes providing and maintaining a work environment that is without risks to health and safety.

2. Health and Safety at Work (General Risk and Workplace Management) Regulations 2016

- Risk Management: PCBUs must identify hazards that could give rise to reasonably foreseeable risks to health and safety and eliminate those risks so far as is reasonably practicable. If elimination is not possible, risks must be minimised.

• Personal Protective Equipment (PPE): PCBUs must provide PPE to workers unless it has been provided by another PCBU. PPE must be suitable for the nature of the work and any associated risks, and it must be maintained, repaired, and replaced as necessary.

3. Health and Safety at Work (Hazardous Substances) Regulations 2017

- Hazardous Substances: PCBUs must manage the risks associated with hazardous substances, including ensuring that substances are correctly labelled, stored, and handled. Workers must be trained in the safe use of hazardous substances.

4. WorkSafe Guidelines for the Provision of Facilities and General Safety in the Construction Industry

- Site Safety: Guidelines include requirements for fencing and securing construction sites to protect the public and workers. This includes ensuring excavations are fenced, materials are stacked safely, and plant and machinery are immobilised when not in use.

- Public Safety: Adequate security measures must be in place during non-working periods to prevent unauthorised access and potential hazards.

5. Workplace and Facilities Requirements

- Workplace Conditions: Workplaces must be clean, healthy, safe, accessible, and well- maintained to ensure work can be carried out without risks to worker health and safety.

By adhering to these regulations, fencing businesses can ensure they are providing a safe working environment and protecting their workers from potential hazards.

In conclusion, maintaining our equipment is crucial for ensuring the safety and efficiency of our rural operations. By keeping detailed maintenance logs and addressing repairs promptly, we can prevent downtime and extend the lifespan of our tools. Let’s continue to prioritise safety and diligence in our daily tasks.

Together, we can achieve a productive and successful fencing season. Stay safe and keep up the great work!

Best regards,

Deb and the RuralSafe Team

Published in WIRED issue 76/March 2025 by Fencing Contractors Association NZ

You may also like: Health & Safety News

Read WIRED online

Follow us on Facebook

© Fencing Contractors Association NZ (FCANZ)