I enjoy getting on with people and sharing knowledge; the offer seemed a great next step to take. What I enjoy about tutoring is the variety of people I meet from all ages and areas – ranging from very experienced fencers to new members of the fencing industry. You never stop learning and sharing ideas.

Who?

|

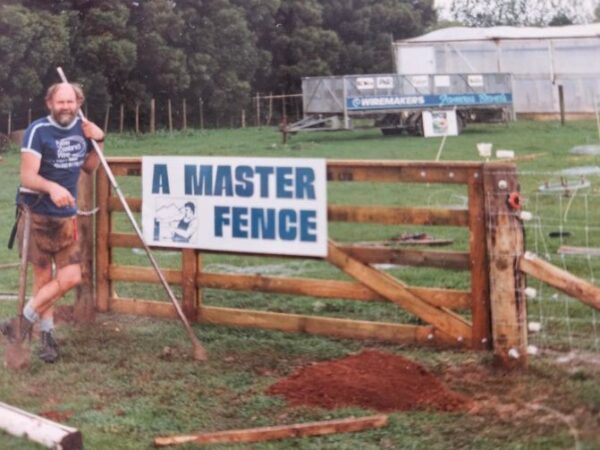

I set a high standard of workmanship and enjoy sharing knowledge, which led to me being asked if I would like to tutor one of the first Certificate in Fencing (Level 3) courses for NorthTec | Te Pukenga in the South Island, about four years ago. |

At times, it can be challenging taking people from the level of work they do, to the higher quality of workmanship that is necessary to achieve Level 3 & 4 qualifications. Enhancing students’ learning, to me, is sharing ideas and treating people how you want to be treated. It goes a long way in life.

I make mistakes as easy as anyone, but the right thing to do is to go back and put them right. When you make a mistake, learn from it and share it with others. It’s a learning curve. Work as a team. It’s attention to detail that wins out.

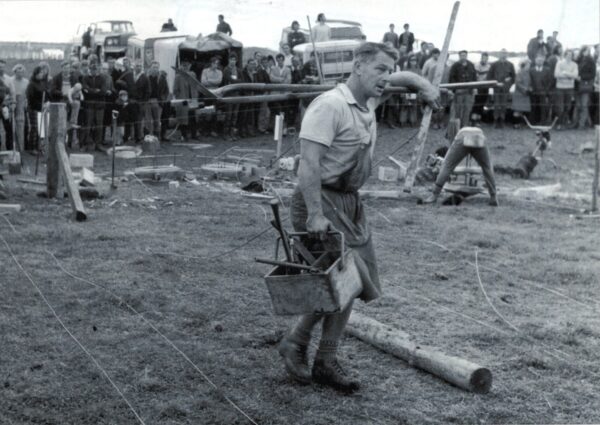

Going to Fieldays and watching competition fencing will help with technique and take you to the top of your game. Make sure you attend FCANZ’s Best Practice Days, as you will get heaps out of it – there’s a wealth of knowledge to be gained from FCANZ Partners and other contractors from around the country. Don’t be afraid to ask questions.

Some of the best moments I’ve had while tutoring have been seeing students work in all the different and amazing countryside and types of ground conditions, from drilling solid rock to silt, and everything in between. From flat land to high country, it all has its challenges.

Memorable moments

One of the best feelings ever is to see seven of my students (including Amanda Beckham) enter the NZFC fencing competition at the Kirwee Field Days, and to witness one of my Level 3 students, Michael Conijn of Custom Fencing (Dunedin), receive the Trainee of the Year award at the FCANZ Conference this year. Michael is a great team player, doing outstanding work. The women attending the courses show great attention to detail in their work.

If you’re coming into the fencing industry, gaining the Level 3 and Level 4 qualifications will be a huge benefit to you and your business – it proves you have attained and demonstrated a high standard of knowledge and workmanship, with attention to detail. Setting high standards and holding qualifications has got to be great for the fencing industry. The world is your oyster; get out there and go hard (with health and safety at the forefront of all activity, of course).

What other career offers you the ability to have a new office every day!?

Cheers, Noksee.

Article written by John Noakes

Published in the Professional Development Feature in WIRED Issue 71 / December 2023 by Fencing Contractors Association NZ

You may also like: Industry training key to moving business forward

Follow us on Facebook

© Fencing Contractors Association NZ (FCANZ)