With construction sites and subdivisions popping up in most districts, there is an ever-increasing need for safety and environmental controls to be implemented. In this “Diversity in Fencing” feature article Nick Liefting talks about civil site fencing.

We are all accustomed to the health and safety protocol by now and am sure it is well embedded into each of our psyches. Environmental issues are also becoming just as important and I know a lot of us who are faced with it almost on a daily basis, it too has become part of our psyche.

So, in this article, I will explain the issues surrounding these two very important topics.

HEALTH AND SAFETY

Induction

Before we start work on-site, we must go through the induction, which can take anywhere from two hours to as much as a day (yeah you heard correctly). In the induction, the following items are spelled out:

- Dangers

- Contact personnel including the first aider

- Hours of work

- Housekeeping

- Drug testing

- Nature of the site

- PPE to be worn

- Nearest A&E

We will then sign a register to confirm the induction and often get an induction number.

PPE

As well as mandatory high viz jackets, lace-up boots, and hard hats, it is becoming increasingly common for gloves, glasses, ear protection, long sleeve shirts and long trousers. To be worn ALL THE TIME. No fun in the Auckland summer!! On some sites, they have personnel specifically designated to watch for anyone not complying – then it is instantly off-site.

Our responsibility is to produce a site-specific hazard register, along with our company Health and Safety Policy.

We must also have our own toolbox meeting before we commence work, which basically states what we will do that day and the hazards to be aware of. This must be recorded and signed by each of us. It only takes 15 minutes and can be done on the way to site.

All this you might think is a hassle and a half, and yes, I do agree, BUT, if something goes bad, WorkSafe is certainly looking who to ‘point the finger at’. And believe you me, I have had this happen first hand.

Not all that many years ago, we were asked to install 120m of farm fence on a sub-division and for whatever reason, one of my staff got his hand under the post driver weight, and yes you know what happened, ‘Whamo’, lots of blood and a finger gone. Fortunately, my foreman had all the relevant paperwork in place and WorkSafe checked the machine etc, and realised it was the worker’s own stupidity. He is now permanently on a benefit. Like they say, ‘you’ve gotta have all your ducks in a row’.

I will often factor induction time into whatever I am pricing for the site.

SITE FENCING

Due to the specific consent requirements spelled out by the relevant local authority and nearby residents, the fencing can be quite involved, namely:

- Safety fencing

- Silt fencing

- Super silt fencing

- Dust fencing

- Acoustic fencing

- Security fencing

SAFETY FENCING

This is primarily used to keep the public out of hazardous areas, e.g., silt ponds, deep excavations, and high machinery traffic zones. It is also often used to fence around the drip line of protected trees and historical sites, to deter construction machinery from encroaching.

The construction of this fencing is generally outlined in the site plans and is mostly constructed using waratahs at 4.0m centres with a top and bottom wire and high viz plastic mesh attached. As this is an integral part of the overall construction works, the fencing must also be maintained throughout and often well after completion. At times, the mesh will need to be replaced as the UV breaks it down.

Safety fencing must also be installed above any structure that is over 1.0m high, e.g. retaining walls.

SILT FENCING

We are fortunate to live in a country that has strict environmental controls. This makes it rewarding when we are out enjoying our leisure activities, as there are countries that belch anything into the air and send anything and everything into the waterways.

Of course, living in this pristine country comes at a price. Environmental controls on construction sites can be an expensive commodity, which obviously must be passed on to the end-user.

There are many environmental controls but I will talk about silt fencing. Silt fencing is used to hold back silt runoff, just like a farm fence is to hold livestock back.

It is installed on the lower end of an exposed surface where vegetation and/or topsoil has been removed, and often at the base of earthworks stockpiles.

It is common for the plans to show the extent of the silt fencing, plus the Engineer can also direct where additional silt fencing is to be installed.

Prior to inclement weather approaching, often contractors are frantically upgrading and/or refurbishing silt fences to ensure all is secure, and yes, we have been on previous occasions called to a site mid-afternoon Friday to do just that – it doesn’t put a ‘smile on one’s face’.

It has happened that silt fences haven’t coped with the sudden deluge of silt and therefore failed, causing silt to go where it is not supposed to. The consequences to the contractor are not nice. Abatement notices and fines of tens of thousands of dollars are not uncommon.

With an Abatement Notice, all work on-site must stop until the silt control is adequate and has been inspected by the territorial authority. This of course does not do wonderful things for one’s attribute portfolio.

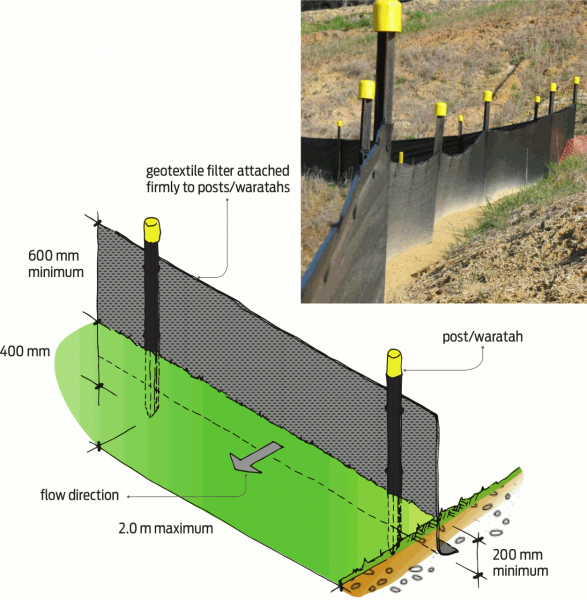

CONSTRUCTION OF A SILT FENCE

- Dig a trench 200mm deep with a narrow bucket.

- On the downhill edge of the trench, install waratahs, or supports of equal strength, 3.0m apart (2.0m apart if working on a small construction site).

- Install one wire approximately 400mm above ground and another at approximately 800mm above ground.

- Use 1.20m wide designated silt fence cloth and clip to the top wire then lay in the trench and backfill. I find from experience, it is best to have it lay across the trench with dirt on top, as I have seen them blow out on a windy site. There is no need to attach to the lower wire.

- When joining silt fence cloth, roll both ends on a batten, then nail the battens together.

- Along the length of the silt fence, a 3.0m return is generally installed every 40m or as designated by the Engineer, depending on the catchment. This is to slow the run-off down.

The silt fence remains in place until the grass has taken, or areas have been sufficiently covered in mulch, and there is no potential for silt runoff.

SUPER SILT FENCE

This fence is similar to a standard silt fence, but more robust, and used primarily if there is a greater slope uphill of the silt fence, and/or potential of larger and stronger silt flows.

The construction has a wire netting or mesh attached to the wire before the silt cloth is attached. The super silt cloth is double thickness, with the top 200mm single thickness for ease of installation.

Silt cloth also comes in an orange colour to double up to use in a high viz zone.

Also, you don’t need to apply much, if any, of your Golden Pliers expertise for the construction. What’s more important is what I have explained.

DUST FENCING

This is a very real issue and is often demanded by local residents. With the constant tracking of earthmoving machinery, copious amounts of dust can be generated. Throw some wind into the equation, well Mum next door won’t be at all happy when she is hanging out her washing!

It is common for the contractor to have water cart trucks fixed with sprinkler booms solely dedicated for the purposes of dust control. However, if for whatever reason this is not practical, then a dust fence can be erected.

The construction of this as we have previously done is a 4.0m high windbreak fence, as used in the horticulture industry. This will have a sprinkler hose attached on top which will be emitting water continuously. Dust fencing is not all that common, as most sites are not completely surrounded by residential properties. If there are properties nearby, the prevailing winds could well be blowing away from them.

ACOUSTIC FENCING

As much as we can have silt and dust pollution, so can we have noise pollution. With a lot of sites operating 7.00am to 6.00pm, there can often be people still asleep and families having dinner. A lot of acoustic fencing can be a permanent structure if close to busy roads and noisy facilities.

Most acoustic fencing is constructed using timber or concrete, which obviously absorbs the noise. On the recent widening of the South Auckland motorway, there was a significant quantity of concrete noise barriers installed. They attached a stainless-steel wire grid and have now successfully grown vegetation against the wall.

There was a situation not that long ago, where Land Transport, in their wisdom, installed a significant metal screen noise fence on the Manurewa Hill portion of Auckland’s Southern Motorway. As I travel this section frequently, it was sometime later that this structure was completely removed. The noise was magnified due to the bouncing and echoing effect of the steel barrier.

The most common acoustic fence structure is a timber paling fence, 2.0m high. At the base, a ground treated 150mm x 50mm rail is placed firmly onto the ground. The paling configuration can be either:

- 150mm paling with 100mm gap and another 150mm paling placed over the gap

- 150mm paling attached with no gap and a 50mm paling secured over the join

- 150mm paling attached with the next 150mm paling placed 25mm over the previous one.

SECURITY FENCING

On most construction sites, a security fence is paramount around the perimeter. This fence is obviously temporary until construction work is complete and permanent boundary fencing can be installed.

The purpose of the security fencing is to keep ‘Joe Public’ off the site and lessen the risks of potential accidents.

The construction of security fencing is either diamond mesh or deer netting, using timber posts. These are often installed without concrete for ease of later dismantling. Regarding deer netting, yes, I know you need big end assemblies etc, to give the tension required. Often sites can have many angles, plus ends for gateways. However, we are not dealing with livestock, but people who would climb the fence. So ask yourself the question, “Which is easier to climb? – a tight netting or one that is a little more on the saggy side”? As a further deterrent, a barbed wire is often placed on top of the posts.

Article provided by:

Nick Liefting of Nick Liefting Contractors Ltd

Published in the Diversity in Fencing feature of WIRED December 2021 by Fencing Contractors NZ

Follow us on Facebook

© Fencing Contractors Association NZ (FCANZ)