There can’t be many fencing contractors who can thank wine for contributing to their business’s success. But such is the case for Marlborough based family business Renner Fencing Contractors.

Terry Renner started fencing in 1968 with Dymoke Clunies-Ross, teaching him how to fence to the high standards set by Dymoke.

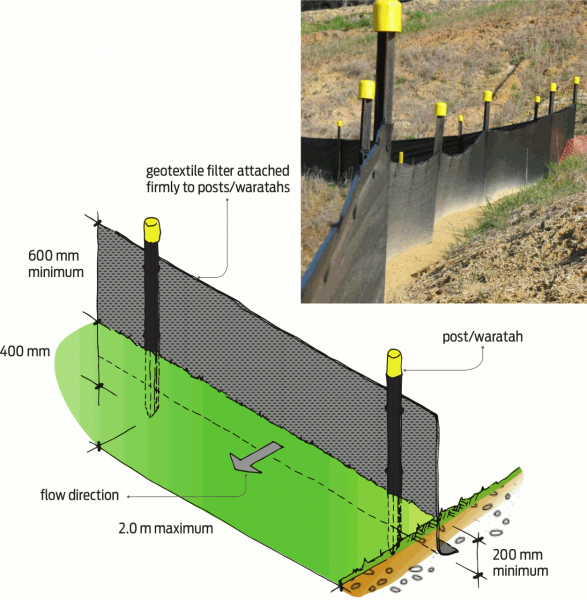

Materials used back then were flat standards, T-irons for angles and railway sleepers for end strain assemblies, with concrete posts starting to being used on the flats. Treated posts and BHP waratahs were to follow.

Shearing was Terry’s first venture into self-employment, having learnt to shear as a young man. A shearing gang was employed in 1989, adding to the fencing business, and taking the business from two to 16 staff. And thus, Renner Contracting Ltd, was formed.

The shearing run was sold in 1998, with Renner Contracting managing a farm and the fencing business. Five years later, the business purchased one tractor (leasing a second), along with two Taege post drivers and started working on vineyard developments.

Bradley Renner was the first of Terry’s sons to leave school in 1991 to help with a big fencing job up on Muller Station. Bradley was only 15 and not enjoying school at the time.

Michael (Mike) was pulled out of school in his 7th form year once the first XV rugby was over for the season. Both boys worked at the local freezing works and fenced in the off season. They also dabbled in the woolsheds from time to time, picking up other skills like wool handling, penning up and pressing the wool, and picking up the handpiece.

In 2001 Mike did what many of his peers did and took off for his OE, taking his shearing and fencing skills with him. While in Scotland he picked up some useful residential fencing knowhow and on his return to New Zealand, started up a residential fencing crew at Renner Contracting. KC Fence Systems provided training for the installation of their security fencing which expanded the business’s service offerings further.

Mike & Bradley brought into Renner Contracting in 2008 when the freezing works closed down. The money received from their respective redundancies went towards a deposit on a new tractor and truck. Both sons received a 25% share each in the business, with Terry retaining 50%. Renner Contracting continued to specialise in vineyard development and fencing, going from 4 staff to 8 permanent and 6 casual staff.

Terry says of the vineyard development work, “We were doing full development, starting with laying out of the posts, strainers and stays, driving intermediates with a subcontractor with post drivers until the diggers come on the scene. Strainers were hit in with the Taege Posts drivers and the stay done with a digger. Wire running and irrigation was run out to finish off.”

With demand for vineyard work piling up, Renner Contracting had to expand their machinery “from two tractors, two Utes, a motor bike and two trailers, refinancing to have three tractors and buying a new Revolution Post driver followed by a second a few years later” says Terry.

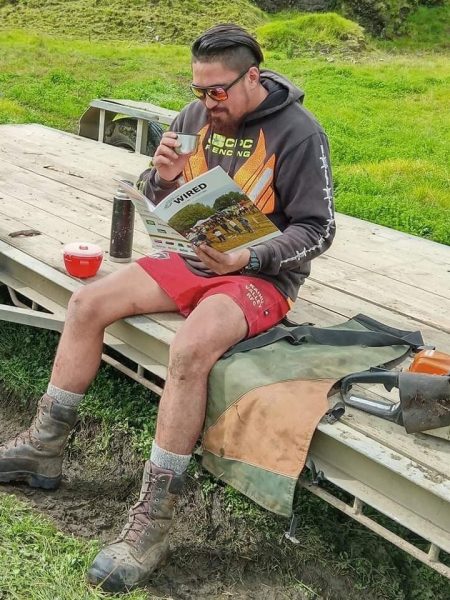

Mike took over the quoting side of the business in 2012 and was managing it after hours, while remaining on the tools full time (a position many fencing contractors will recognise). There came a point, Mike says, where it got too much, and elected to put a day or two aside for looking at jobs and quoting.

“I quite enjoyed the variety of keeping my hands on the tools and some paperwork. As time has gone by and with help from a business mentor, I have put down the tools to steer the ship, so to speak, running four fencing crews. I now meet new clients looking at jobs, quote, sort materials, assign staff the next job and invoice.”

Health and Safety takes up a lot of Mike’s time, along with the daily admin of emails and phone calls.

“The days have gone where the farmer calls you on the landline in the evening with a job” Mike says. “You’d turn up on the job with no phone at work, and no paperwork done. A handshake was the contract for the job.”

Owning and operating a business in 2022 comes with a different set of challenges and opportunities that business owners have to acknowledge and embrace.

“We live in a paperwork and technology-run world now and if you don’t move with it, you get left behind” says Mike.

Terry semi-retired in 2021 and is now paid an hourly rate for the odd hours he does running materials around and “checking in on the crews to make sure Dymoke’s high standards are kept in place and are in good health” he says.

Renner Contracting has been restructured further to recognise the wider family involvement and contribution. Terry now holds a 30% shareholding, with Mike holding 24%, Olivia Renner (Mike’s wife) owning 11%, Bradley 24% and Michelle Renner (Bradley’s wife) owning 11%.

The future of Renner Contracting looks solid, with both Bradley and Mike’s sons showing an interest in fencing. And, even if they don’t end up in the family business, with Terry keeping the grandkids busy during the school holidays by working for the business, they’ll know the satisfaction of a hard day’s work and have some incredibly useful life-skills to take forward into adulthood.

Article written by Mike & Terry Renner and Heather Kawan

https://www.rennerfencing.co.nz/

Read WIRED online

Follow us on Facebook

© Fencing Contractors Association NZ (FCANZ)