All Rural Fencing Ltd started back in 2002 when we moved to Snells Beach after selling our 700-head dairy farm.

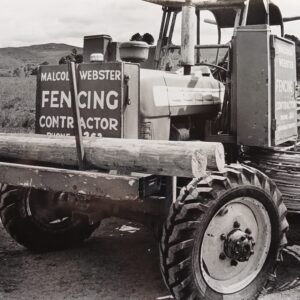

However, before going dairying, I realised I needed money to buy a herd, so, at the age of 18 years I went fencing in the Maungaturoto area. I built my first post driver during that time.

Both in dairy farming and fencing, I have always looked for ways to improve and make the way we do things easy. So many others just do what they have been taught and don’t improve.

So often, it’s the simple things that make a difference. I mounted a box on each side of the tractor bonnet to hold tools and things we need in our daily work. It saves having to either go back and forth to the Ute or drag a trailer over rough ground.

Wire spinners are mounted on pipes attached to a front-end loader bucket. The wires spin off these, go through guides down the side of the tractor to the post driver and run out behind the tractor. When setting up to fence, we drive the strainer post in, then attach one wire and drive down the fence line, putting in corners to the strainer at the other end.

We strain this tight, and it becomes the single guide wire. Next, we walk along the line, spacing out the post positions with the plumb bob string touching the wire. We allow the plumb bob to touch the ground and carefully spray a line which will indicate where the wire side of the post will go in. This allows us to take tension off the guide wire and drive along the line post driving without the guide wire getting in our way. This method is quick and efficient.

Once all the posts and stays are in, we attach three wires to the end strainer, drive down the line to the other end, cut and tie them, then turn around and go back. All seven wires are ready to be put on.

Next, using a wire threading tool that I designed and made, we walk along the line, stapling all the wires in the correct position. Then, we strain in the middle of the line using a tension gauge and permanent wire strainers, which completes it ready for battening.

Over the years, my fencing has included deer and construction site netting, using my designed netting unroller/tensioner attached to the post driver.

We also pull out a lot of fences, some of them very rubbishy, using my designed V-lifter for lifting posts, and a hydraulically driven old fence winder, which winds up old fence with wires and battens still attached.

Using my specially designed drill bit, we put in and pull out vineyards, enabling the planting of new vines.

When pulling out vineyards, we use our wireless remote controlled tractor mover and a special lifter for lifting out vine plants and posts. As the tractor moves down the line, and when hanging gates, we use my counter sinking drill bit.

Our business has diversified in many ways and continues to do so. Over the years, we have fenced and/or developed a children’s playground, rose arbour (80m x 4m), wedding arbour with grape vines over top, retaining walls, cattle yards, the list goes on.

Written by Malcolm Webster

Published in WIRED issue 76/March 2025 by Fencing Contractors Association NZ

You may also like: Adapting and Evolving – JB Fencing’s success story

Read WIRED online

Follow us on Facebook

© Fencing Contractors Association NZ (FCANZ)