A perfectionist who took pride in his work

There was a time in Frank Prince’s life when he did not consider fencing as a profession. Fortunately, as his family recalls, he ‘fell into it’, leaving behind a legacy of dedication, commitment, and a high quality of workmanship that set a benchmark for New Zealand fencing.

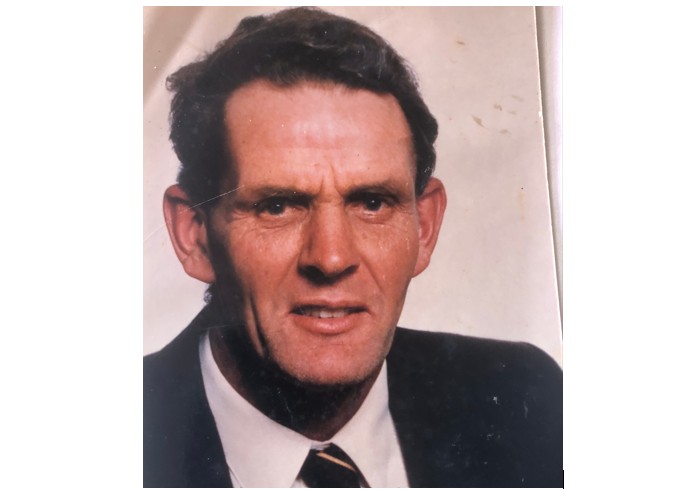

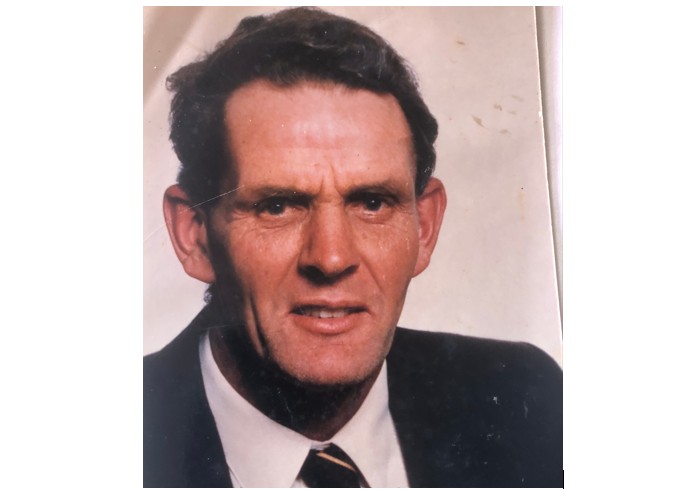

Francis John Robert ‘Frank’ Prince was born on 25 June 1941 in Whanganui. His father, Frederick ‘Frank’ Prince Snr, worked as a fencer in the greater Whanganui district around Marton and Turakina his whole life. Travel wasn’t as straightforward then as it is now, and staying local offered many good work opportunities. He and his wife raised a family of six children: daughters Josephine and Janice, and sons Frank Jnr, Louis, Neville, and Maurice.

Frank Snr fenced at a time during the Second World War when timber was plentiful in New Zealand but wire wasn’t. Three-wire was the norm, all work was done by hand using a post hole borer for the strainers and angles, and stays were chopped with an axe. Frank Snr died at the age of 92, having fenced well into his 70s.

As a young man, Frank Jnr had no desire to be a fencer like his father, although he had learned basic skills by helping out on jobs after leaving school. Instead, he became an engineer/boilermaker, doing his time on the railways. As an apprentice, Frank helped to construct a railway bridge over the Whanganui River at Aramoho. This bridge, still in active service today, is one of the few riveted bridges remaining in New Zealand. It was built on top of the old one and then lowered down onto it.

Moving from a boilermaker to a fencer was quite a transition for Frank. Fencing was still not his profession of choice, but he took it up professionally after he and his wife, Marie, purchased a lifestyle block in the small farming community of Maxwell, about 20 kilometres west of Whanganui.

Frank married Marie in 1961, and they had four children: Robert, Rick, daughter Tracey, and the youngest, Marcus. They raised their family on the Maxwell block of three acres divided into six paddocks, including the yard and garden. They had dairy cows, a pig, and a house cow that kept them in milk and butter. Marie remembers having 41 pounds of homemade butter in the deep freeze one time.

The mid-80s offered opportunities with the rapid development of horticulture in New Zealand, and Frank worked extensively with Jim Erickson, who was the ‘guru’ in this expanding industry.

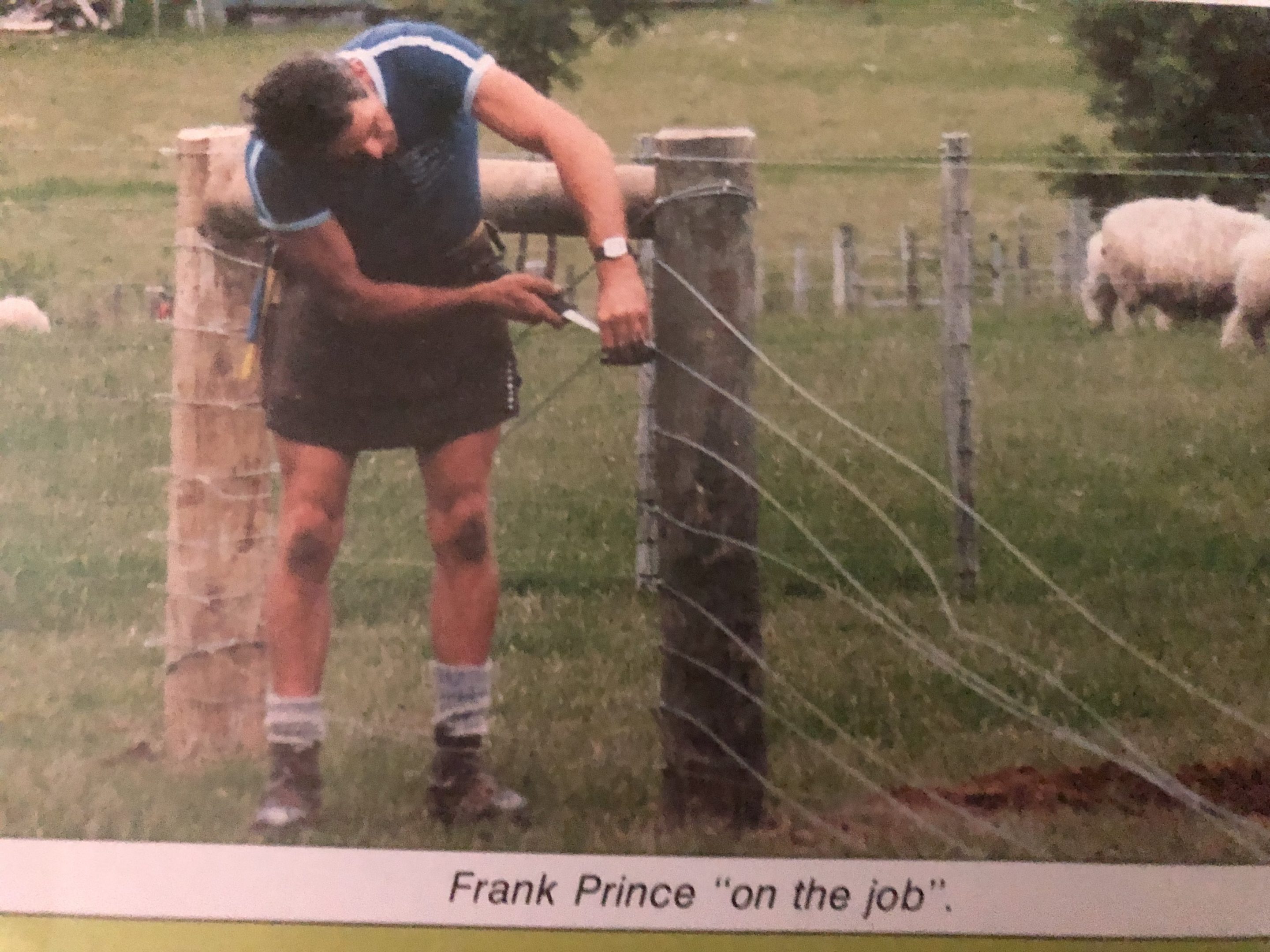

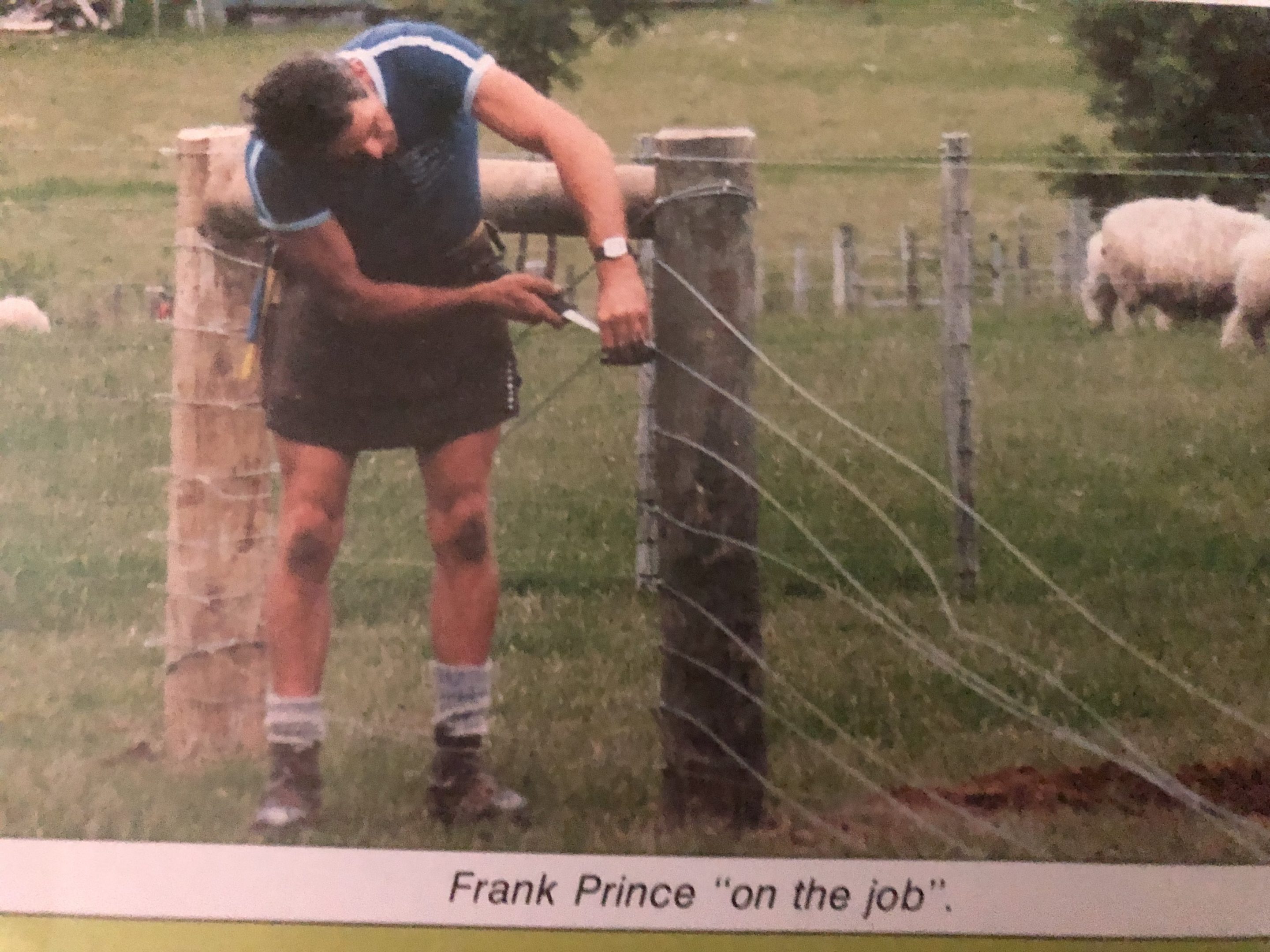

Frank worked in areas around Whanganui, including Raetihi, Ohakune, Waverley, Bulls, and the Whanganui River, sometimes staying away from home when the jobs were big. One of the first major jobs he took on was a 10km deer fence up the river. He usually had brother Neville working with him and hired others from around the Maxwell district, many of whom ended up with him at Fieldays as part of a large group from Whanganui. Fencing was a ‘family affair’ with Robert, Rick, and Tracey all helping out. Rick recalls getting “a truck and trailer load of materials every week, that’s a load of timber, and we were putting that in the ground each week.”

Frank wasn’t big on machinery and often made or modified his own equipment. He dug posts in by hand. Robert remembers, “Dad swore he’d never use a post driver, waste of money, saying the bloody tractor and driver would be sitting doing nothing”, but he gave in during his last big job in 1997. He and Robert installed 25km of electric fencing in 24 days, each working with a post driver. “He never went away from post drivers after that!”

Marie claims credit for one job where she told Frank to construct a mole plough for an underground cabling job. “The plough was highly sought after when we sold the Maxwell land, and Frank would never admit it was my idea to get it.”

Tragedy struck the family in 1985 when Marcus was killed by a driver under the influence of drugs or alcohol. Marcus had just turned 18 and had been working with his father at the time of the accident. Marcus and another boy travelling in the car lost their lives.

There was a time later on when Marie and Frank broke up for a while. Marie moved to Pukekohe where her sister lived, and remembers “Frank couldn’t live without me”. He sold the family block at Maxwell and joined her. “Selling that block was huge,” Marie recalls. “It was a big move. Frank was born and bred in Whanganui, so leaving there was a big thing for him.”

Pukekohe proved to be a good move for Frank, as he found the work plentiful. People on lifestyle blocks with money to spend employed him for property fencing, and he did a lot of horse double fencing too, plus maintenance and engineering work.

Fieldays beginnings and competitive fencing

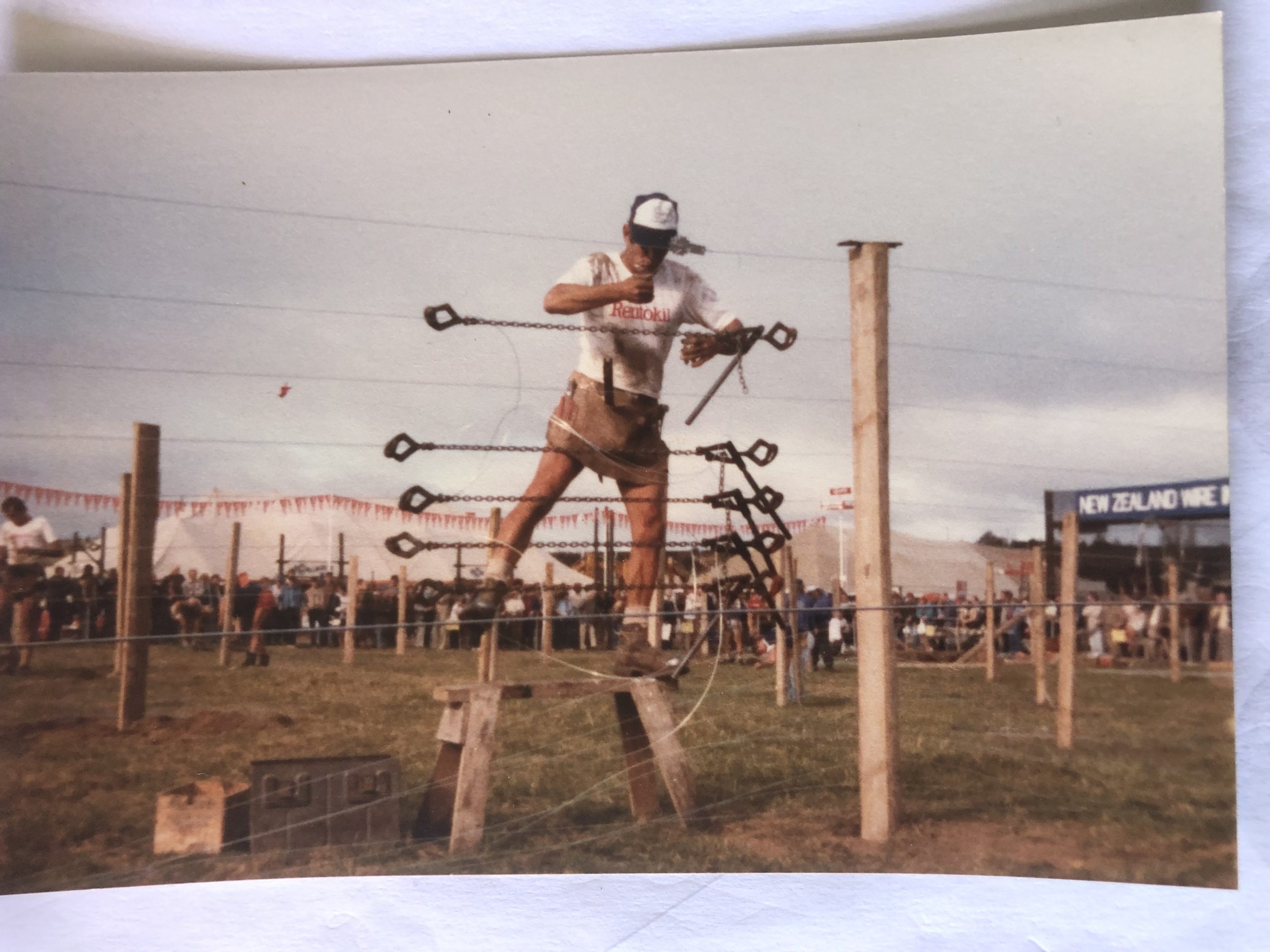

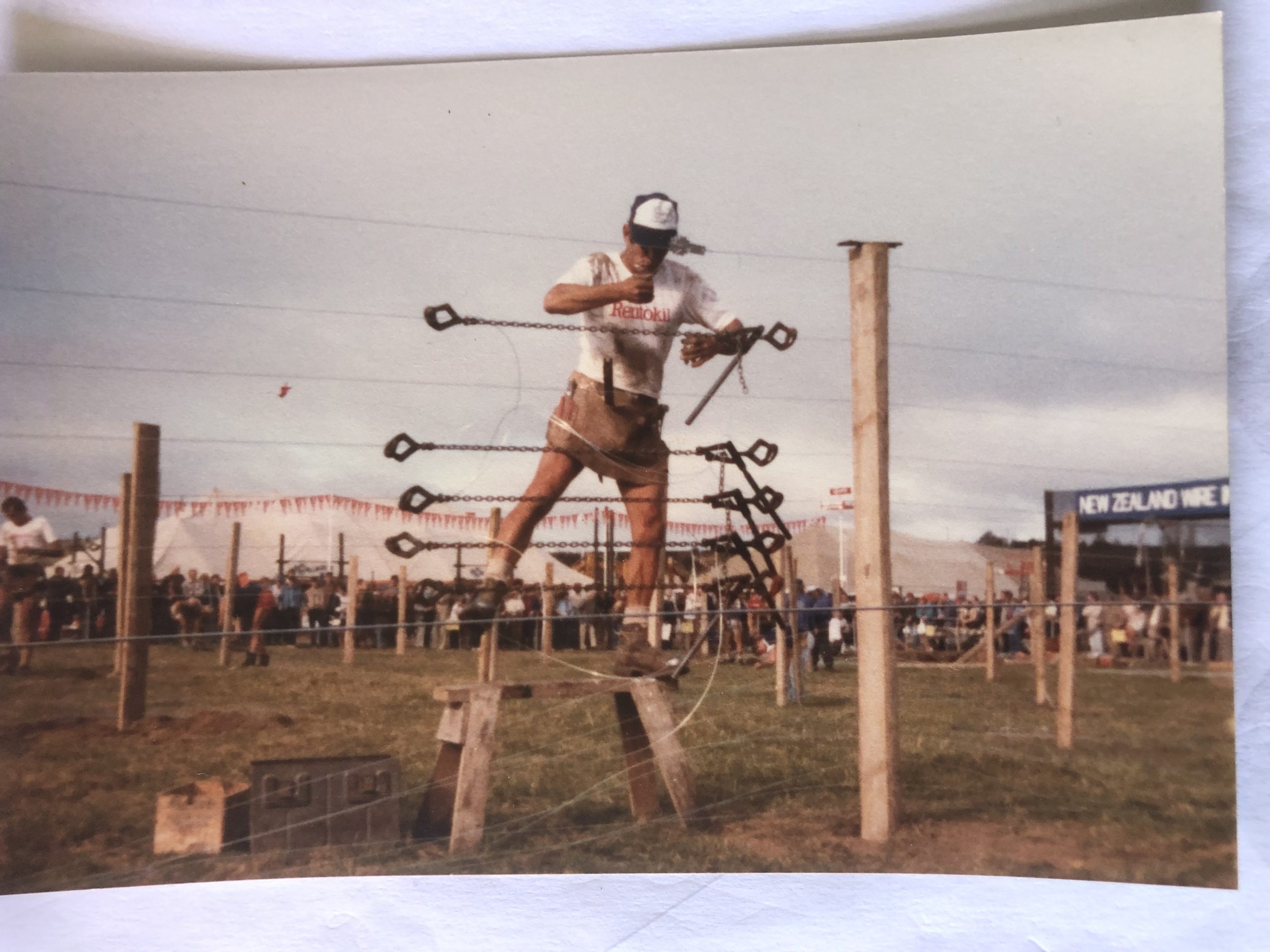

A visit to Fieldays in 1975 with Neville sparked an interest in competitive fencing. An oftheard saying is, ‘Watching won’t do anything for you’, and there were hard lessons in store for the brothers. After driving up that first time in Neville’s Chevy truck, True Blue, the brothers stood on the sidelines, confident they could take on the competitors and ‘kick their backsides’. That first attempt ended in a sobering outcome that had them retreating with tails between their legs. Undaunted, they swallowed their pride and returned year after year. Fieldays became the annual holiday. It was the only competition venue in the country at the time, and everyone wanted to have a go.

Frank entered the competitions every year from 1976 to 1988, appearing in two Golden Pliers finals with a best of third place, and five Silver Spade finals with a best placing of fourth, a notable achievement as he had a different partner each year.

Competitors often say, “That’s where you really learn to fence”, watching top-class fencers showcase their skills within a competitive environment that demands not only speed and skill but high-quality craftsmanship too. In those early years of Fieldays, many attended for that reason, to acquire knowledge, familiarise themselves with the high standard required, and to learn from champion fencers. For Frank, the learning curve was one he mastered and took into his own professional work. Partner those skills with his engineering background, and you had a recipe for perfection and fences that have lasted for 20-30 years plus.

Frank competed at Fieldays for a few years until giving up competition to judge the Golden Pliers event. He also judged at the regionals in Waverley, one of the longest running and largest events of the time. Frank’s sons competed there; however, he did not judge them.

Teaching, leadership, and national influence

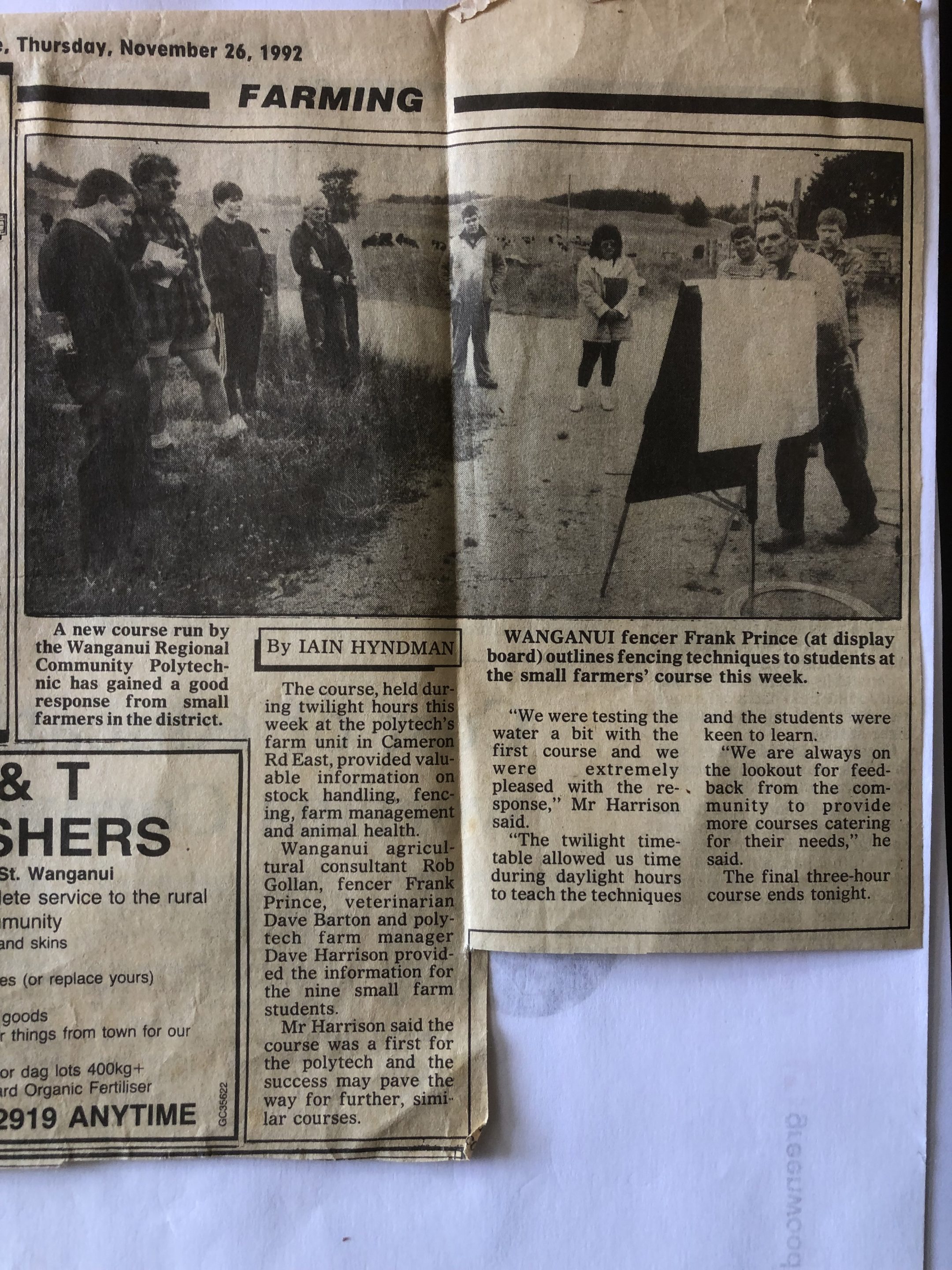

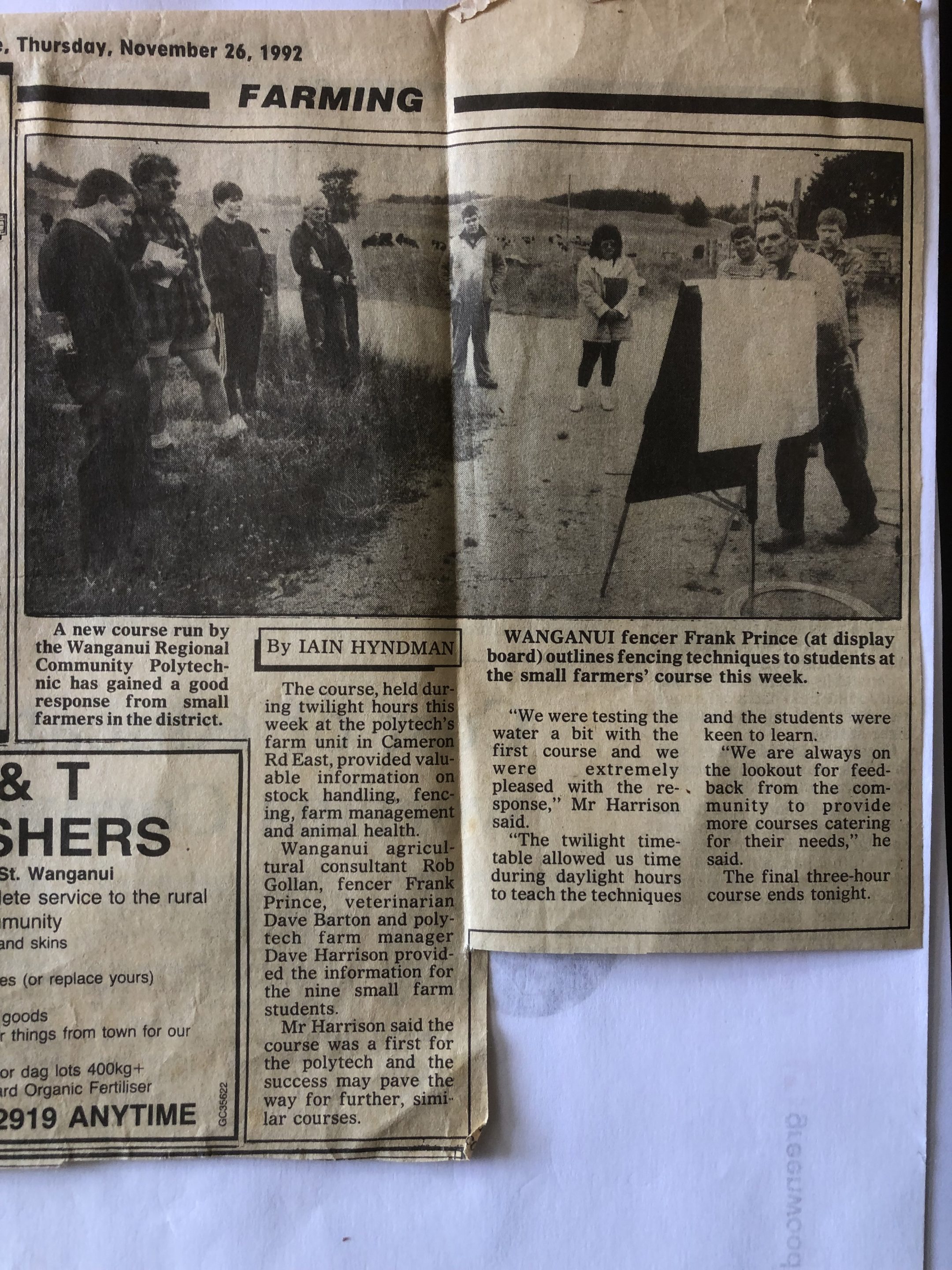

Frank’s expertise, ability to share his knowledge and to nurture young talent saw him taking over the position of NZ Wire Chief Instructor from Bill Schuler in 1987. He was responsible for overseeing around 30 instructors nationwide, delivering courses in the many fencing training schools throughout the country.

The role required expertise in the technical aspects of fencing (for example, multi-strand wire, loadings, wind breaks) – an area in which Frank excelled – and, coupled with his work in the developing field of deer fencing, quarantine work, shelter belts, and horticulture. Frank is remembered by so many as a skilled educator and role model. Frank travelled extensively, holding demonstrations at fencing schools that were innovative for their time, popular, and well attended. Frank collaborated with the NZ Agricultural Engineering Institute to write the manual for the Master Fencer course (launched 1986/87, no longer active today), intended to offer fencers a qualification (NZ Wire Industries National Certificate in Fencing) additional to the Golden Pliers. In 2016, Frank was recognised for his training work, receiving a Lifetime Award from the Fencing Contractors Association of New Zealand.

Retirement, legacy, and final years

Frank retired at 79, working full-time right up to the day. Marie said it was “bull’s wool” to claim he was part-time because “… he was on call, worked full-time and most weekends if there was something going, because he loved fencing.” There was no shortage of jobs as Frank was so well known and respected for the quality of his fencing.

As Frank’s health deteriorated, moving home to Whanganui felt right. He enjoyed reading books, and a friend of Tracey’s would send down boxloads from Rotorua, making sure he was never short of a good selection. He also loved his phone, keeping up with the world news and happenings.

Frank and Marie were married for 64 years, and she remembers him saying to her, “I don’t think we’ll see our 65th.” Frank passed away at home on 28 September 2025, aged 84, surrounded by family.

Frank was proud of his work, and rightly so. Much of it has stood the test of time. He made significant contributions to the development of fencing in New Zealand, both as an educator and a skilled and highly respected fencer, and leaves behind a legacy that will continue to inspire for years to come.

Written by Nick Liefting

Published in WIRED issue 79/December 2025 by Fencing Contractors Association NZ

You may also like: Tough toil in life brings an empathy for others

Read WIRED online

Follow us on Facebook

© Fencing Contractors Association NZ (FCANZ)